Magnetic template for milling machine

Realization of maximum flexibility and productivity

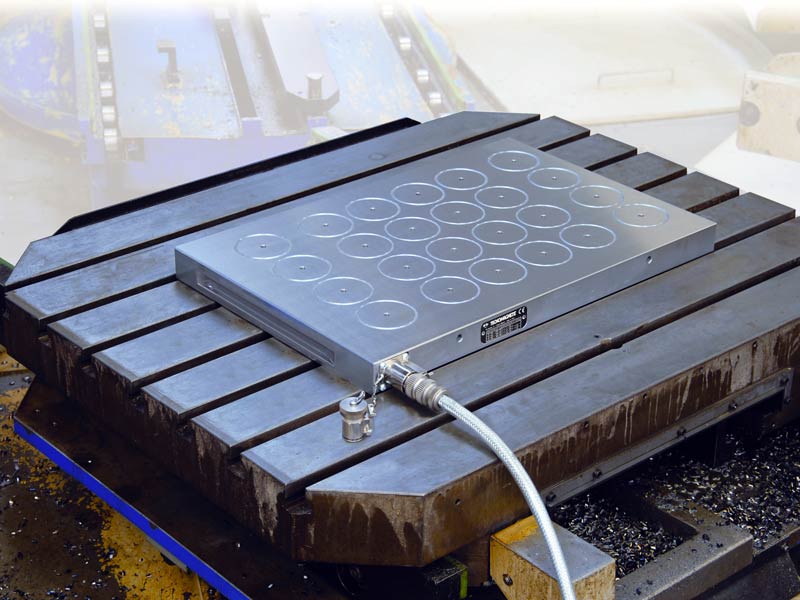

The innovative machining disk system MillTeck offers various powerful, secure disks and is widely used in high-speed and heavy-load processing operations.

MillTec disk provides an ideal solution for horizontal and vertical machine tools, mobile platforms, mobile pillar processing platforms, machining centers and other FMS system processing platforms.

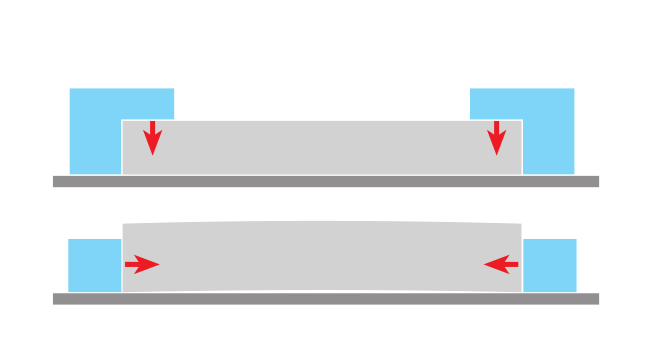

Uniform clamping force

When clamping the workpiece with the auxiliary fixture, the machining process is inevitably interfered, which makes the tool unable to contact each machining surface of the workpiece, and multiple clamping is required during the machining process.

MillTec provides a consistent clamping force on the workpieces contact surface so that the workpiece is not subject to compression deformation

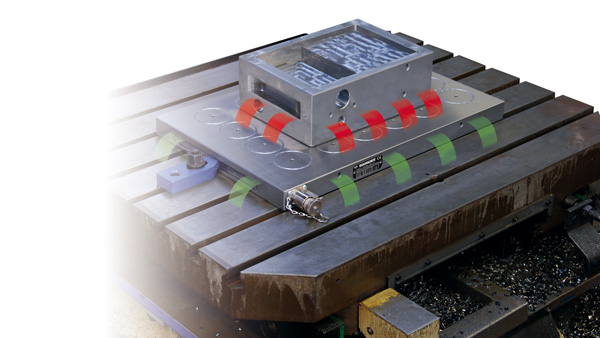

Self-priming and rapid stress release

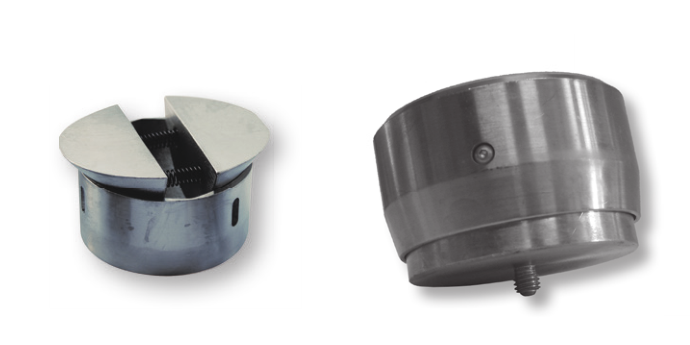

The new generation of independent floating magnetic conduction block RMP copes with processing of all kinds of workpieces, making the operation easier and more practical. Circular magnetic pole and integral thread pin make positioning simple and fast. No any tools are required to avoid any possible mistakes.

The RMP magnetic deduction block is designed to prevent any iron chips and debris from infiltrating into it, thus ensuring that no cleaning and maintenance work is required, and that consistent performance is guaranteed for a long and stable period.

The integrated double sloping structure ensures better magnetic flux transfer, and increases magnetic force by 20% compared with the traditional single inclined magnetic conduction block.

International patents

WO 2009/007807

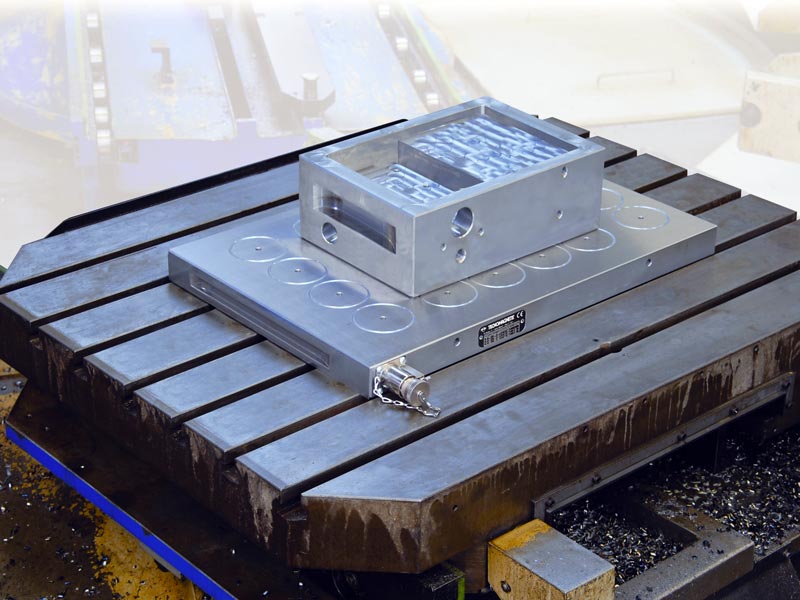

Realization of omnidirectional machining with one clamping

MillTec allows the workpiece to be completely machined on 5 sides after one clamping, and improves the processing path of various processing operations (milling face, drilling hole, forming milling etc.), and reduces greatly the time of clamping replacement for multi-batch workpieces processing.

Modelling processing and through-hole drilling hole

Integrated fixed magnetic conduction block with different height can lift workpiece away from disk surface and can easily realize all processing steps of workpiece.