The idea of innovation locks the workpiece and the equipment directly

GRIP function

The clamping force at the bottom of the disk is 30 of the surface of the disk. Each magnetic pole on the disk surface produces 640DaN magnetic force, while the bottom magnetic force is 200DaN. GRIP function can produce powerful magnetic force and lock tightly with machine tool table.

The workpiece / disk and machine tool table become a whole with magnetic clamping, greatly improving accuracy and reducing tool loss. When the surface of the machine is smooth and flat, the magnetic force between the disk and the machine is maximum as the machine closely contacts with the bottom of the disk.

Suitable for any machine tool

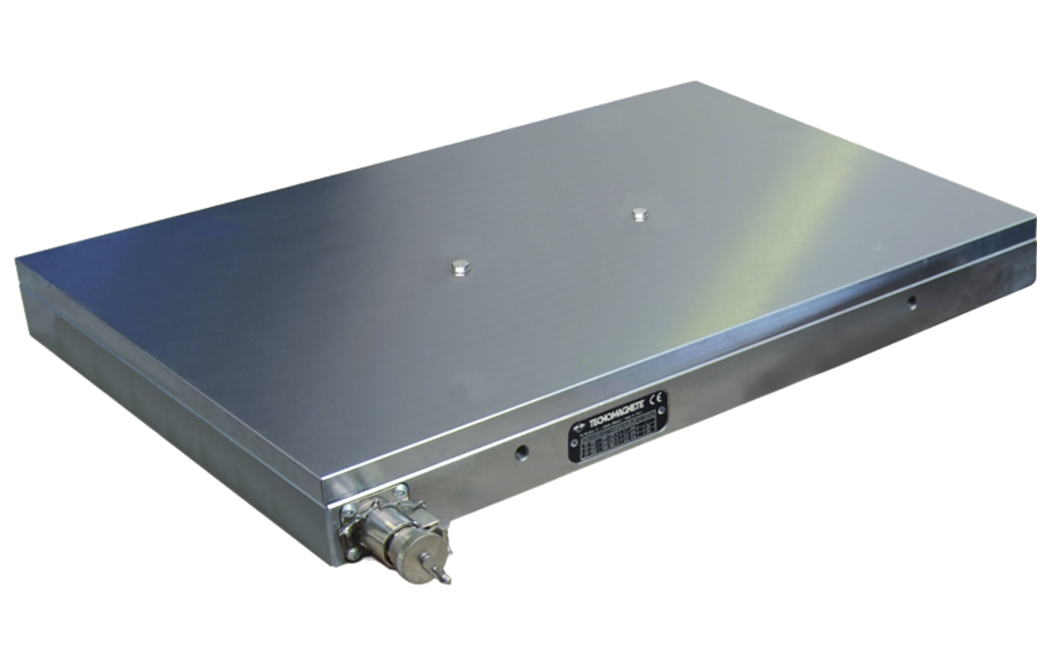

The magnetic disk is equipped with two standard spaces in case the disk needs to be bolted. Backup plate randomly provided by factory plays a key role in disk installation and disk transshipment and can be reused when transhipping the disk.

Fixed holes

Backup plate

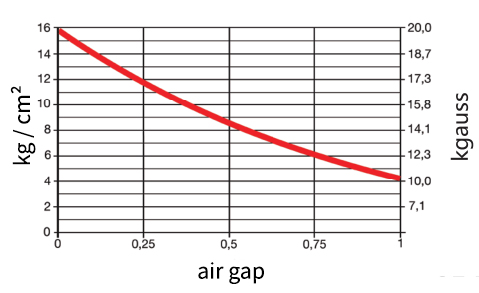

Magnetic force VS air gap curve chart

Milltec processing instance

Workpiece size: 410 × 260 × 50 mm, with three fixed magnetic conductors PFR 70 / 45 and nine floating magnetic conductors RMP 70 / 45. Positioning

Materials: FE275 JR. Equipment: VMC 1600 – 27kW

Disk specification: MillTec Grip 304HD (320 × 425 × 42mm), bottom magnetic locks on machine tool

| Milling surface | Milling groove | Edge milling | |||

| DC | Tool | mm | 125 | 50 | 50 |

| Zn | Tool length | n. | 8 | 5 | 5 |

| n | Cutting speed | rpm | 860 | 1800 | 1800 |

| ap | Cutting depth | mm | 1.5 | 2 | 5 |

| ae | Cutting thickness | mm | 80 | 50 | 5 |

| Vf | Feed plane | mm/min | 400 | 5000 | 4000 |

| Q | Rate of cutting | cm3/min | 480 | 500 | 100 |